Understanding Structure, Not Technique

Introduction

Many makers would like to create adjustable silk kumihimo bracelets without relying on metal findings. One common challenge they face is keeping the silk kumihimo sliding knot secure. In practice, yet, this often leads to frustration:

- sliding knots that gradually loosen

- adjustments that do not stay where they are set

- inconsistent results, even after repeated attempts

This naturally raises the question:

“Is my technique wrong?”

This article does not explain how to tie knots.

Instead, it focuses on why loosening occurs from a structural perspective. It also examines the material perspective. This is often the missing piece in this discussion.

Loosening Is Structural, Not a Defect

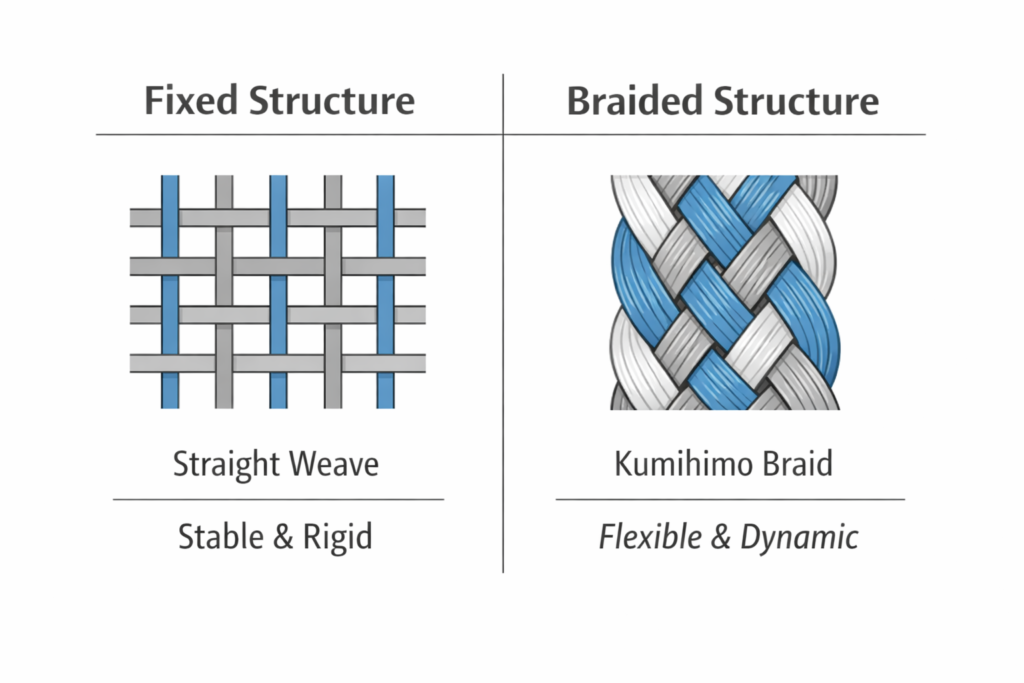

Kumihimo is not built from threads fixed in straight vertical and horizontal directions.

It is formed by multiple strands that cross diagonally and support one another within a cylindrical structure.

This diagonal interlacing is fundamental to all braided cords.

While it provides flexibility and strength, it also means the structure inherently allows a small degree of internal movement.

When tension is applied, force does not stay at a single point.

Instead, it is distributed diagonally through the braid.

From a textile-engineering perspective, this behaviour is well documented in studies of braided structures.

The Role of Silk as a Material

Silk further amplifies this structural behaviour.

Compared with synthetic fibres, silk is:

- highly flexible

- smooth at the fibre level

- relatively low in friction

As a result, within a sliding knot or adjustable section, strands do not “lock” rigidly.

They stay in a balanced state, where position is maintained by friction and tension rather than absolute fixation.

This is not a flaw, nor a sign of poor workmanship.

It is the natural outcome of combining a diagonally braided structure with a low-friction, flexible fibre.

Why “Perfectly Fixed” Sliding Knots Are Unrealistic in Silk

With silk kumihimo, it is generally unrealistic to expect sliding knots to stay completely immobile under all conditions.

Unlike synthetic cords, silk does not respond well to designs that assume permanent locking.

The more practical approach is not to remove movement entirely, but to control it within acceptable limits.

In other words, the goal is stability, not rigidity.

What Can Help Reduce Loosening

While no solution can remove movement entirely, certain factors can help improve stability.

In general, using a kumihimo cord that is:

- more tightly braided

- higher in structural density

- firmer in overall construction

may help reduce the degree of loosening.

This is less a matter of knot choice and more a matter of material choice and braid structure.

Even so, silk will always keep some degree of movement by nature.

Professional Craftsmanship and Realistic Expectations

Well-made adjustable silk bracelets do exist.

Nonetheless, their success is not based on a single trick or universally reproducible method.

Rather, it reflects accumulated experience in material choice, braid structure, and finishing control.

These factors decide how movement is managed, not eliminated, in a finished piece.

Understanding these limitations helps set realistic expectations when working with silk.

Conclusion

Silk is a demanding material.

It requires a different mindset from synthetic fibres, particularly in adjustable designs.

By understanding the structural behaviour of kumihimo, makers can make informed design decisions. They consider the material properties of silk without chasing an impossible level of fixation.

Rather than forcing silk to behave like a rigid material, the key lies in designing with its nature.

FAQ – Silk Kumihimo Sliding Knots

Q1. Why do silk kumihimo sliding knots loosen over time?

Silk kumihimo sliding knots loosen because of the braided structure and the nature of silk itself.

Kumihimo is made from strands crossing diagonally, which allows internal movement.

Silk fibres are smooth and flexible, so friction inside the braid is lower than with synthetic materials.

Q2. Is loosening a sign of poor knotting or bad technique?

No.

Some degree of loosening is structurally unavoidable with silk kumihimo.

It is not necessarily caused by poor technique, but by the interaction between diagonal braid structure and low-friction silk fibres.

Q3. Can sliding knots be completely fixed when using silk cord?

In most cases, no.

With silk kumihimo, perfectly fixed sliding knots are unrealistic.

The goal is usually to control movement within acceptable limits, rather than to remove it entirely.

Q4. Why do synthetic cords behave differently from silk?

Synthetic cords generally have higher surface friction and less fibre flexibility.

This allows sliding knots to lock more firmly.

Silk behaves differently because of its smooth surface. Its natural flexibility makes it less suitable for designs that rely on permanent locking.

Q5. Does using a tighter braided kumihimo cord help?

It can help reduce loosening to some extent.

A more tightly braided, denser cord offers greater stability. Yet, it will not completely eliminate movement when silk is used.

Q6. Is this article a tutorial on how to tie sliding knots?

No.

This article explains structural and material principles only.

It does not describe knotting ways, production steps, or techniques.

Q7. Are adjustable silk kumihimo bracelets still practical to wear?

Yes.

Well-designed silk kumihimo bracelets are intended to balance adjustability and stability.

They allow slight movement, but they are designed to stay secure during normal wear.

Q8. What type of cord is better suited for adjustable designs?

In general, a more tightly braided and denser cord can help improve stability.

For reference, examples of tightly braided kumihimo cords used in jewellery making can be found here:

→ Kyoto Silk Kumihimo Cord

This FAQ addresses common questions about silk kumihimo sliding knots from a structural and material perspective, not from a step-by-step or instructional viewpoint.

Further Reading / Academic References

The structural principles discussed above are supported by research in textile engineering and materials science.

For readers who wish to explore these topics in greater depth, the following academic references provide useful background.

Structure and Mechanics of Braided Fabrics

This research outlines how braided textile structures distribute force through diagonal strand arrangements, allowing controlled internal movement rather than rigid fixation. It provides a fundamental explanation of why braided cords behave differently from woven or twisted structures.

https://www.sciencedirect.com/science/chapter/edited-volume/abs/pii/B9780081026199000079

Geometrical Modelling of Braided Textiles

This study examines how braid angle and diagonal strand configuration influence the mechanical behaviour of braided textiles. It is particularly relevant for understanding how density and geometry affect stability and movement within cylindrical braids.

https://eprints.nottingham.ac.uk/76624/

(search term: geometrical modelling braided textiles)

Analysis of Circular Braiding Processes

This research focuses on circular braiding structures, analysing friction, strand interaction, and structural density. It offers insight into how cylindrical braided cords manage tension and internal displacement under load.

https://asmedigitalcollection.asme.org/search-results?q=Analysis%20of%20circular%20braiding%20process

(search term: circular braiding process)

These references are provided for contextual understanding of braided textile behaviour and are not intended as step-by-step production manuals.

Note

This article discusses structural principles only.

It does not describe specific knotting methods or production techniques.