A practical reference for jewelry makers and textile designers

Choosing the correct cord thickness can significantly impact the final look of a jewelry piece. The choice of material also affects the jewelry’s durability.

This guide serves as a reference for jewelry makers. It also aids textile designers who want clear, reliable information when selecting cords for their projects.

Thickness Guide

Japanese braided cords are flexible structures rather than rigid components.

Their thickness is influenced by material, braid structure, and tension during production.

Fine cords

Approx. 0.7–0.8 mm

Suitable for beads with small holes, delicate pendants, and layered jewelry designs.

This thickness is often chosen when the cord needs to pass through bead holes while remaining visually subtle.

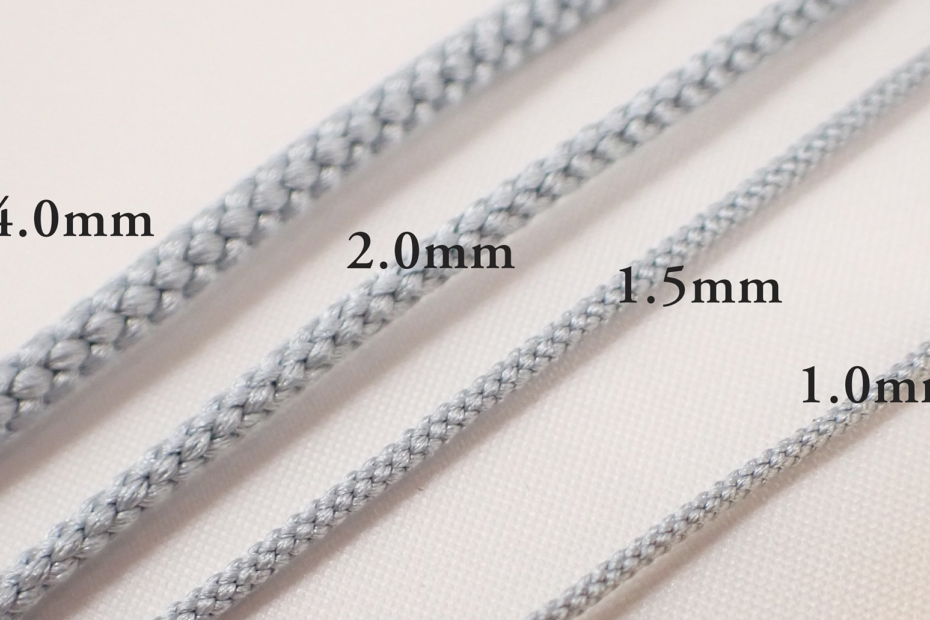

Standard cords

Approx. 1.0–1.5 mm

Suitable for necklaces without beads, end caps, closures, and decorative ties.

This range offers a balance between flexibility and presence, making it widely used across jewelry and textile applications.

Thick cords

Approx. 1.8–2.5 mm

Suitable for statement necklaces, decorative knots, and designs where the cord itself is intended to be a focal element.

This thickness is not typically used for threading beads. Nevertheless, it works well when the cord’s structure is part of the visual design.

Because these cords are braided rather than extruded, a slight variation in thickness is natural and expected.

Material Comparison

Silk Cord

Material characteristics

Natural silk fibre with a soft, refined texture and a subtle sheen.

Typical uses

Fine jewelry, traditional-inspired designs, and projects where surface feel and elegance are important.

Handling notes

Silk cords should be handled gently during finishing and assembly, especially when attaching metal components.

Polyester and Synthetic Cords

Material characteristics

High durability, stable color performance, and consistent structure.

Typical uses

Daily-wear accessories, projects requiring strength, and color-focused designs.

Handling notes

Synthetic cords are generally more resistant to friction and moisture, making them suitable for repeated handling.

Colour Library

Japanese braided cords are available in a wide range of colors, including subtle tonal variations.

When reviewing color options, it is helpful to:

- Compare similar shades side by side

- Consider how color interacts with cord thickness

- Evaluate color balance considering surrounding materials

Please note that colors are different depending on lighting conditions and screen settings.

For close shades, side-by-side comparison is recommended whenever possible.

Choosing Colours for Your Project

When selecting colors, consider:

- The scale of the project and cord thickness

- The surface finish of beads or metal parts

- Lighting conditions in which the final piece will be worn or displayed

Muted tones often emphasise texture and structure, while vivid colors highlight braid patterns and contrast.

Care & Handling Notes

To guarantee consistent quality in the long run:

- Avoid prolonged exposure to moisture

- Store away from direct sunlight

- Handle gently when attaching metal parts or end caps

Braided cords work best when treated as both structural and decorative elements rather than rigid components.

Conclusion

Selecting the appropriate thickness, material, and color is a practical decision that directly affects both handling and visual balance.

This guide serves as a resource for evaluating choices or organizing upcoming projects that use Japanese braided cords.

For a full overview of available colors and materials, please refer to our reference pages.

Explore the full color range using our reference pages:

– Silk cord color sample book

– Silook® (polyester) cord color sample book